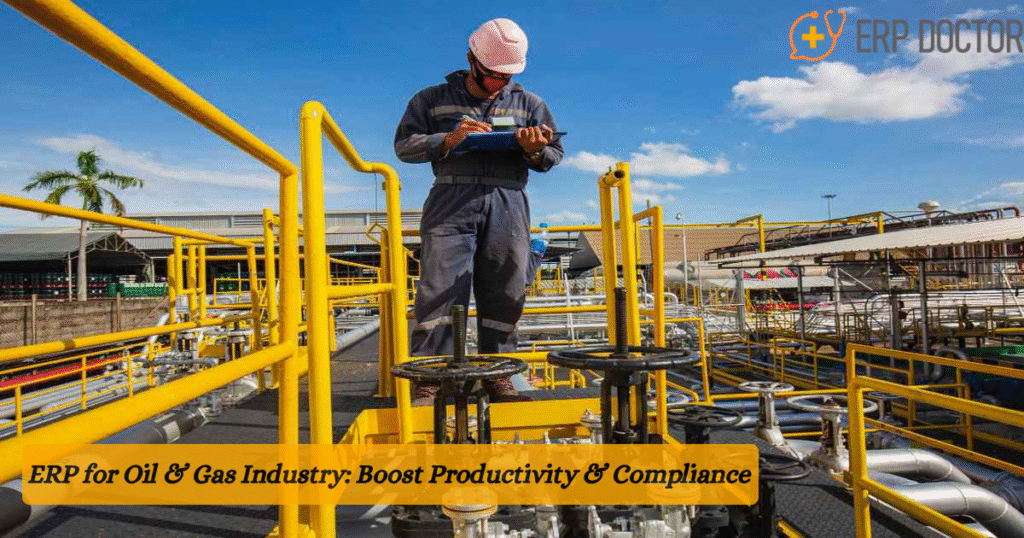

ERP for Oil & Gas Industry: Boost Productivity & Compliance

ERP for Oil & Gas Industry: Overcoming Key Challenges with Smart Solutions

The Oil & Gas Industry faces immense operational, financial, and regulatory challenges. Implementing a modern ERP Software for Oil & Gas is essential for streamlining processes, ensuring compliance, and improving profitability.

To address these challenges, oil & gas companies are increasingly adopting Oil and Gas ERP systems that integrate all operational, financial, and compliance processes into a unified platform. These ERP solutions for oil and gas companies help streamline workflows, improve decision-making, and ensure regulatory compliance enabling organizations to operate efficiently in a volatile market.

Why ERP Is Critical for the Oil & Gas Industry

Managing an Oil & Gas operation involves multiple interdependent processes exploration, drilling, production, inventory management, logistics, maintenance, and financial reporting. Traditionally, many companies relied on spreadsheets or disconnected systems, leading to:

- Data inconsistencies

- Operational delays

- Compliance risks

- High operational costs

A Best Oil & Gas ERP for Small & Midsized Businesses consolidates these processes into one platform, providing real-time visibility, standardized workflows, and centralized reporting. By automating critical operations and integrating departments, an Oil and Gas ERP enhances efficiency and strategic decision-making.c decision-making.

Top Challenges in the Oil & Gas Industry and How ERP Software Solves Them

1. Regulatory Compliance and Safety Management

Challenge: The Oil & Gas Industry is heavily regulated by environmental, health, and safety authorities such as OSHA and EPA. Non-compliance can lead to fines, shutdowns, and reputational damage.

ERP Solution: Modern ERP Software for Oil & Gas automates compliance tracking, maintains audit-ready documentation, and integrates safety protocols directly into workflows. This ensures that every operation meets required regulatory standards efficiently.

2. Asset and Equipment Management

Challenge: Oil and gas operations rely on expensive and complex assets like rigs, refineries, and pipelines. Ineffective maintenance can cause costly downtime.

ERP Solution: Oil and Gas ERP systems include modules for predictive maintenance, asset lifecycle tracking, and real-time monitoring. These features minimize equipment failures and improve asset reliability.

3. Complex Supply Chain and Inventory Management

Challenge: The Oil & Gas Industry operates with vast supply chains across multiple regions. Mismanagement can result in delays, shortages, or excess inventory.

ERP Solution: ERP solutions for oil and gas companies integrate procurement, logistics, and inventory management into a unified system. This ensures real-time visibility, automated reordering, and accurate demand forecasting.

4. Financial Management and Cost Control

Challenge: Managing high operational costs, capital expenditures, and fluctuating commodity prices can be difficult.

ERP Solution: ERP Software for Oil & Gas provides end-to-end financial management with budgeting, cost tracking, and profitability analysis. These capabilities help oil and gas companies make data-driven financial decisions and maintain healthy margins.

5. Production Planning and Operational Efficiency

Challenge: Multi-site operations and complex production processes often lead to inefficiencies and scheduling conflicts.

ERP Solution: Top ERP Systems for the Oil and Gas Industry use real-time data to optimize production planning, resource allocation, and workforce scheduling — improving overall productivity and reducing waste.

6. Data Management and Reporting

Challenge: Fragmented systems create data silos, making it hard to get a clear operational picture.

ERP Solution: Centralized Oil and Gas ERP systems unify data from finance, operations, and compliance departments. Built-in analytics and dashboards provide real-time insights for faster, more accurate decision-making.

7. Risk Management and Predictive Analysis

Challenge: Oil and gas projects involve high risks from environmental hazards to fluctuating market conditions.

ERP Solution: Advanced ERP solutions offer predictive analytics and risk management tools that identify potential issues before they escalate. This allows companies to mitigate risks proactively and maintain business continuity.

Key Benefits of ERP Software in Oil & Gas Industry

Key Benefits of Implementing ERP in Oil & Gas Operations

Implementing a Top ERP System in Oil & Gas Operations brings tangible advantages:

- Improved operational efficiency

- Enhanced compliance and reporting

- Real-time analytics for better decisions

- Reduced operational costs

- Predictive maintenance for critical assets

- Streamlined supply chain and logistics

- Scalability for growing businesses

With these benefits, oil & gas companies can remain competitive, compliant, and profitable ability.

Choosing the Right ERP System for Your Operations

While there are several Top ERP Systems available, the most popular choices include:

- SAP S/4HANA: Ideal for asset-intensive Oil & Gas Operations with modules for finance, logistics, and maintenance.

- Oracle NetSuite: Cloud-based ERP Software for Oil & Gas offering end-to-end financial and project management.

- Microsoft Dynamics 365: Flexible and scalable for production, finance, and reporting.

- SAP Business One (SAP B1): The Best Oil & Gas ERP for Small & Midsized Businesses, delivering affordability and functionality.

Each solution can be tailored for upstream, midstream, and downstream needs, ensuring maximum ROI.

Partnering with ERP Doctor

Implementing an Oil and Gas ERP requires deep industry knowledge. ERP Doctor helps oil & gas companies:

- Select the right ERP platform

- Customize workflows for each operation stage

- Integrate with existing systems

- Train teams and offer ongoing support

With ERP Doctor, businesses can ensure smooth implementation, optimize performance, and drive sustainable growth.e growth.

In today’s volatile energy landscape, a modern ERP Software for Oil & Gas is essential for operational excellence. With the right ERP consulting from ERP Doctor, your business can gain better control, ensure compliance, and stay ahead of the competition

Whether you’re managing drilling sites, refineries, or global logistics, ERP Doctor’s Oil and Gas ERP expertise ensures your systems work smarter, faster, and more profitably.

Top 10 FAQs About ERP for Oil & Gas Companies

Which ERP systems are best for oil & gas companies?

Leading choices include SAP Business One, Oracle NetSuite, and Microsoft Dynamics 365, tailored for upstream, midstream, and downstream operations.

What is ERP for the oil and gas industry?

ERP for oil & gas helps companies manage exploration, drilling, production, refining, and distribution on a single platform. It keeps operations, finance, and compliance connected.

How can ERP improve upstream operations like drilling and exploration?

It tracks drilling schedules, equipment usage, and crew assignments, helping reduce downtime and improve resource planning.

Can ERP help manage pipelines and transportation?

Yes — ERP monitors pipeline flow, maintenance schedules, and logistics to ensure safe and timely delivery of oil and gas.

Does ERP support refinery and processing operations?

Absolutely. ERP can track raw material intake, production batches, quality control, and inventory for refineries.

How does ERP help with asset and equipment management?

It schedules preventive maintenance, tracks asset life cycles, and predicts failures to avoid costly downtime.

Can ERP help with regulatory compliance in oil & gas?

Yes — it automatically tracks safety standards, environmental rules, and industry regulations, including OSHA, EPA, and local laws.

How does ERP optimize the oil & gas supply chain?

ERP integrates procurement, inventory, transportation, and vendor management, ensuring materials and products move efficiently.

Can ERP provide real-time financial insights for projects?

Yes — ERP tracks costs for drilling, production, refining, and transportation, helping companies understand profitability per project.

Is ERP suitable for both onshore and offshore operations?

Yes — ERP adapts to both onshore fields, offshore platforms, and midstream operations, providing a centralized view of all activities.